PRODUCTS

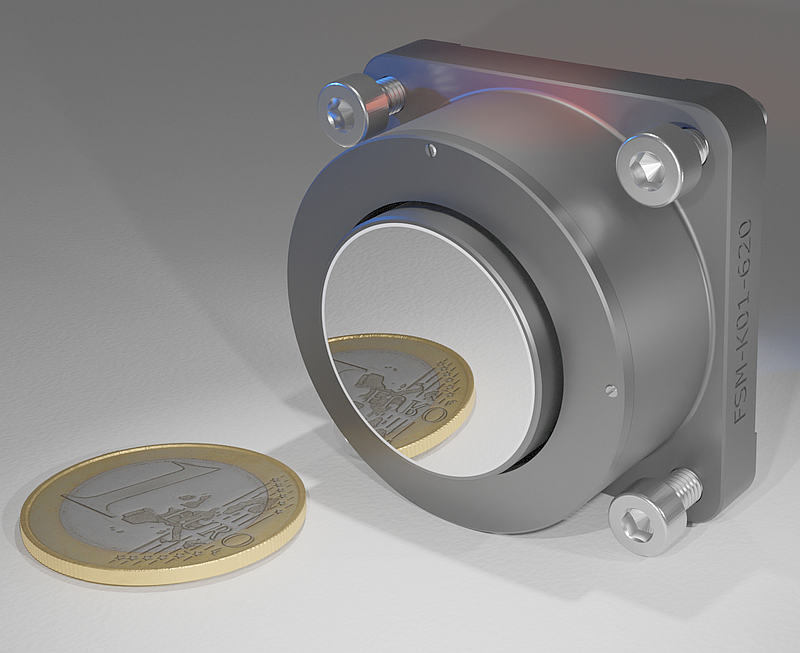

SteerLite Fast Steering Mirror (FSM)

Streamlined Precision in Beam Steering

Fast Steering Mirrors (FSMs) are strategic enablers in demanding applications such as optical communications, Earth observation imaging, medical imaging, and precision metrology. These systems depend on FSMs for beam steering to achieve the required functionalities, and performance.

With SteerLite, Kosmia is developing an innovative FSM that meets challenging demands while reducing complexity and cost — delivering streamlined precision in beam steering.